-

Finnish Consulting Group Design of underground wastewater treatment plant

Finnish Consulting Group – Design of underground wastewater treatment plantProcess and detail design,3D modeling, and P&IDs

Engineering and consulting company uses Cadmatic for demanding and large underground wastewater projects

Customer challenge

- Wastewater treatment projects require CAD software that can handle very large projects without performance issues.

- Need for effective and functional support from software vendor.

Cadmatic solution

- Cadmatic piping design system does not run out of steam in treatment plant projects with 10-hectare area filled with pipes and devices.

- Customer reports Cadmatic is one of only a few software houses that have truly functional support. Problems are often solved on the same day.

“All the largest wastewater treatment plants in Finland have been designed with Cadmatic.” – Petri Poikonen, Planning Manager

An ecological wastewater treatment plant is currently being constructed close to the Finnish capital of Helsinki in Blominmäki, Espoo. From 2021, it will treat the wastewater of around 400 000 of the city’s inhabitants. FCG Finnish Consulting Group Oy is the main contractor for the project. The multidisciplinary consulting company has diverse water know-how and makes use of state-of-the-art project management and design software.

FCG is the main contractor in the Blominmäki wastewater treatment plant project. We started the design work already eight years ago and preliminary design ten years ago. At the moment, we are conducting detail design and the space has been excavated into the bedrock. The construction contractors have been selected and the concrete work should be complete in two years. Finally, partly overlapping with other phases, the devices and piping will be installed. The treatment plant will be taken into use in 2021 and for the time being we are on schedule,” says Petri Poikonen, FCG Planning Manager.

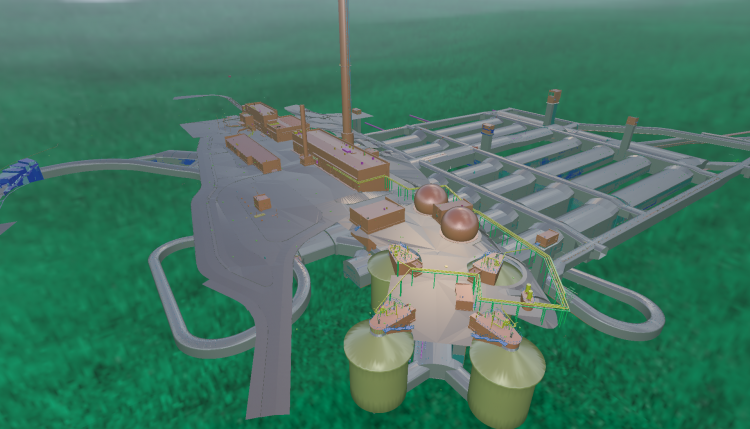

The wastewater treatment plant is being constructed in the bedrock of a 10-hectare area. An underground treatment plant is less intrusive to the surrounding living areas and more ecological. Similar plants have been constructed, among others, in Viikinmäki in Helsinki as well as in Oslo and Stockholm. Buildings have even been constructed on top of the treatment plants.

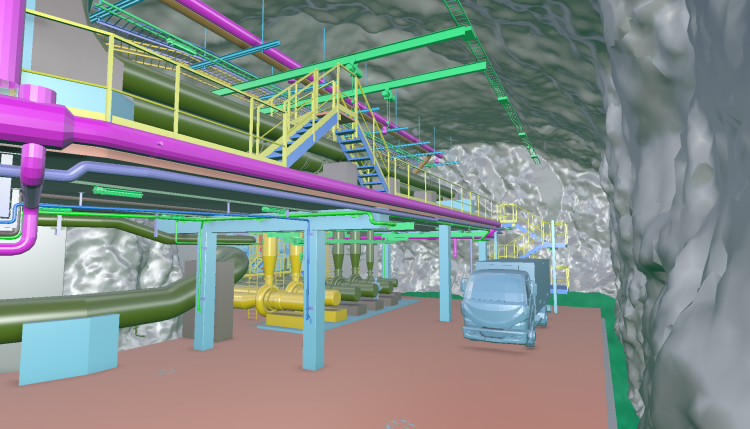

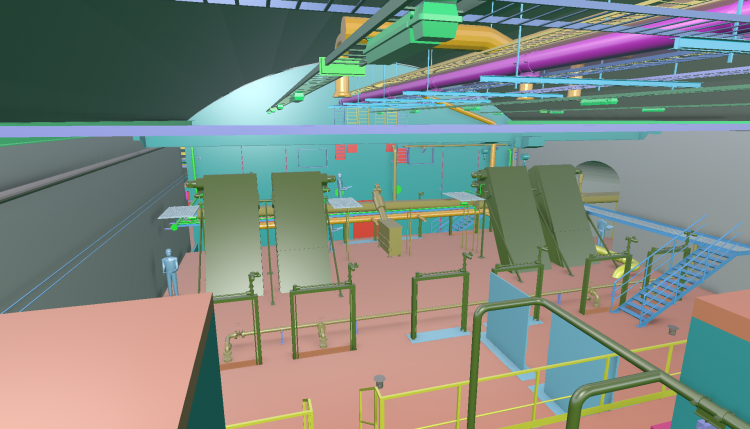

“The bedrock in Nordic countries is of good quality, which allows us to build such treatment plants. An underground plant is out of sight and does not take up unnecessary space. Potential odour problems are also decreased. In Finland, we have top excavation and mine drainage know-how. By building underground we reduce construction costs as the walls and ceilings are ready after excavation. The most challenging aspect of working underground is device installation, as the spaces are compact. All devices, such as HVAC and electrical devices have to fit in the excavated cave. Everything has to be compactly installed and each phase has to be carefully planned.”

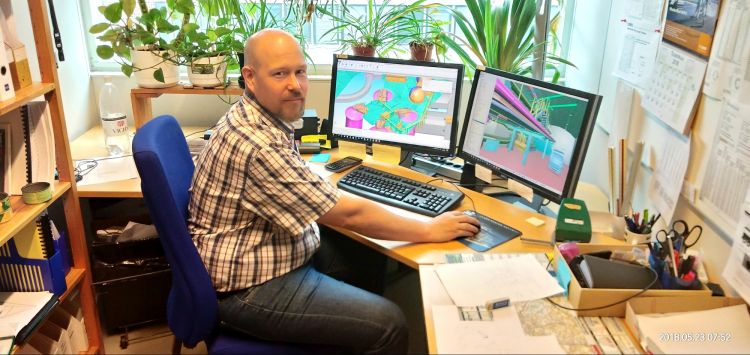

Petri Poikonen, FCG Planning Manager, has been very impressed with Cadmatic’s support services and ability to handle large projects with small teams.During excavation, 300 loads of blasted rock were transported from the underground tunnel to the crushers on a daily basis. In addition, 800 000 m3 was excavated from the supply and discharge tunnels. Wastewater will be brought to Blominmäki from Espoo, Kaunianen, Kirkkonummi, Siuntio and western Vantaa. The inhabitants’ wastewater will flow to Blominmäki in supply tunnels and will be pumped via discharge tunnels into the sea after treatment.

“All the largest wastewater treatment plants in Finland have been designed with Cadmatic.”

Finland’s second biggest wastewater treatment plant was constructed in Suomenoja, Espoo in 1963. It is outdated now and lacks capacity to treat Espoo’s wastewater. The number of inhabitants in Espoo has grown approximately tenfold since 1950. The new treatment plant in Blominmäki will completely replace the old plant in Suomenoja.

“The Blominmäki treatment plant can be expanded to treat up to one million inhabitants’ wastewater. The new treatment plant is very efficient and the discharged water is almost as clean as drinking water. With the new technology, we can almost completely remove the nitrogen and phosphor that cause eutrophication,” Poikonen adds.

FCG: diversified consulting company

FCG Finnish Consulting Group’s mother company is owned by Kuntaliitto Holding Oy. The company’s customers include both the public and private sector. “Most of our commissions come from municipalities, but private sector companies are an important part of our customer base. FCG Group is divided into four main sectors: design and engineering, consulting, training, and international projects. We do many different kinds of plant design, HVAC, electrical and civil engineering, harbour and waterway design, as well as municipal building design, such as hospitals and schools. We naturally also do a lot of water supply and water treatment related design”, Poikonen says.

Wastewater treatment plants around Finland

FCG does all design work related to water treatment. For the public sector, this includes water intake plants, wastewater treatment plants, potable water plants, water towers, booster stations, water networks and environmental evaluations.

“We have designed underground treatment plants before in Viikinmäki, Helsinki and in Kakola, Turku. The inhabitants don’t even necessarily know that there is a treatment plant there, as they are not visible above ground. Only the tall exhaust tower rises above ground level. There are apartment blocks next to the treatment plant and no complaints regarding air quality have been received,” explains Poikonen.

Bedrock treatment plants also allow exhaust fumes like nitrous oxide to be recovered and cleaned. In addition to Viikinmäki and Kakola, FCG has designed Finnish wastewater treatment plants in Klaukkala (Nurmijärvi), Luotsimäki (Pori), Taskila (Oulu) and Metsä-Sairila (Mikkeli). According to Poikonen, all the biggest wastewater treatment plants in Finland have been designed with Cadmatic.

A 3D model of whole Blominmäki wastewater treatment plant.

Cadmatic is the basis of design

Like in many other projects, the starting point for FCG in this project was Cadmatic design tools. It has used Cadmatic on the project for process and detail design, including 3D modelling and P&IDs.

“Our company has a long history with Cadmatic. I think we were their first external customer about 30 years ago in 1987/88 when it was still called Plant Modelling System (PMS). It is our most important tool in plant design. Cadmatic were forerunners in 3D design, and so were we. A very important feature of the software is that it has sufficient capacity to deal with large projects. The Blominmäki treatment plant is a 10-hectare area filled with pipes and devices, which demands a lot from the software. Cadmatic does not run out of steam. Their piping design features are truly world class.”

According to Poikonen, other key software features are reliable support and the distribution of project information.

“Cadmatic is one of only a few software houses that have truly functional support. Problems are often solved on the same day. Projects can also be distributed across our regional offices and shared with the customer. The regional offices and the customer communicate through the Internet and by checking the eBrowser 3D model, which is on the Cadmatic server. The end customer, the Helsinki Region Environmental Services Authority, always sees at most a one-week-old version of the model and can comment on it.”

The Cadmatic tools enable FCG to work with a small team.

“Even a project as big as this can be done with 6 permanent designers and 6 Cadmatic licenses. We have been trained well in software use and have the skills to take on the most demanding design projects,” Poikonen concludes.

A 3D model of the supply pump house.

A 3D model of the screening area.

Read more about Cadmatic solutions

Read more about how Cadmatic's powerful plant design solutions can empower you to tackle massive projects.

< PreviousNext >